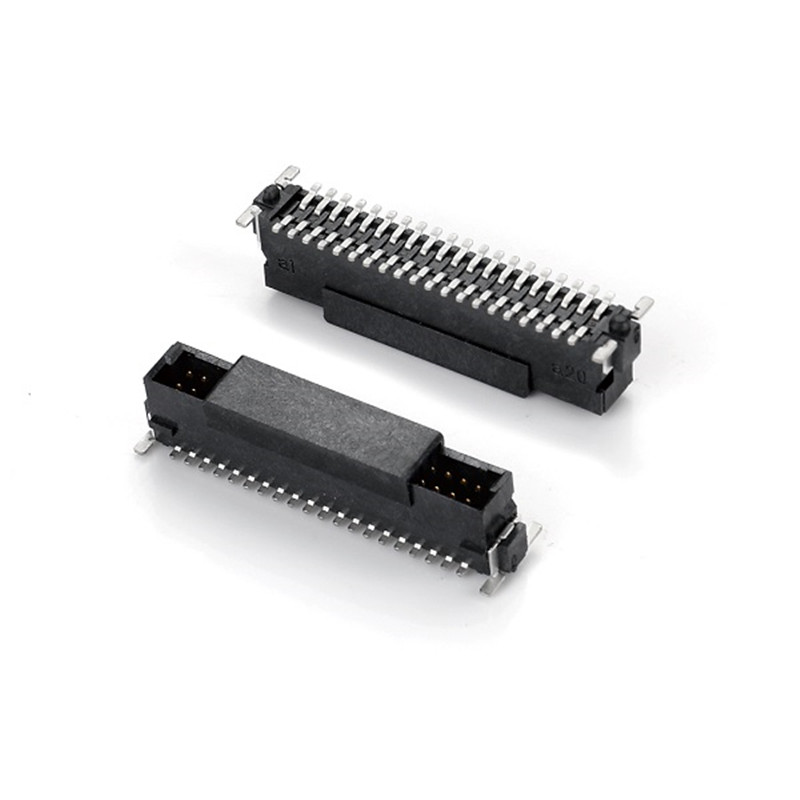

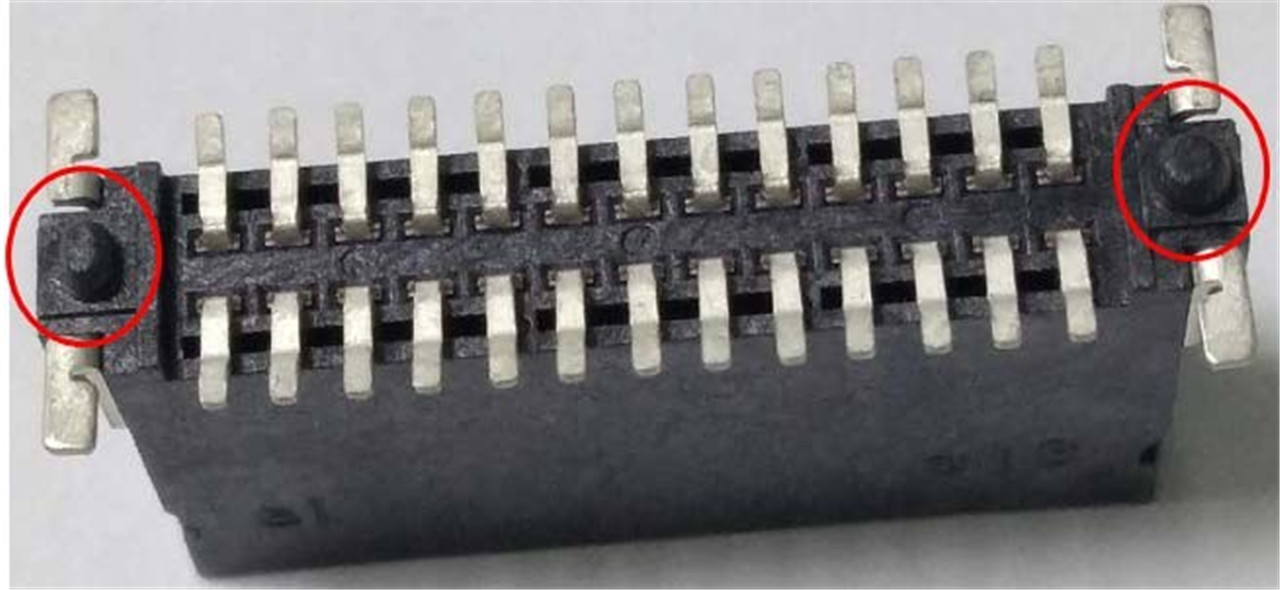

1.27 mm Xidhiidhiyayaasha - Xagasha midig Xidhiidhiyaha lab

Xagalka Midig ee Labka ah

● Tilmaamaha Alaabta

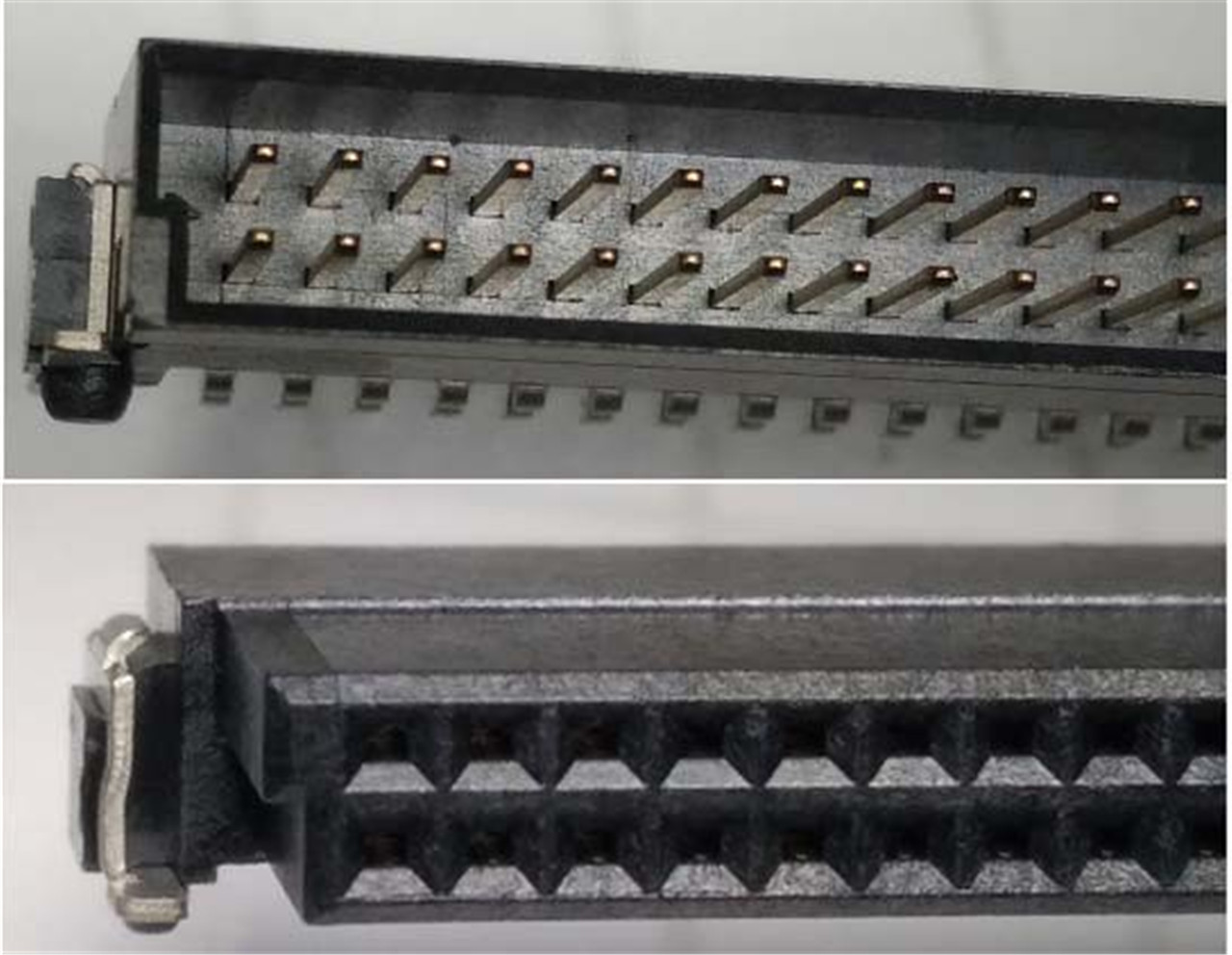

1. Dusha sare

2. isku xiraha laba saf

3. Heerarka xogta ilaa 3 Gbit/s

4. biinanka goobta loogu talagalay meelaynta saxda ah ee looxa

5. Jirka daboolka madow ee aqoonsiga muuqaal degdeg ah oo lagu kalsoonaan karo

6. kulan guddiga si toos ah oo dhamaystiran

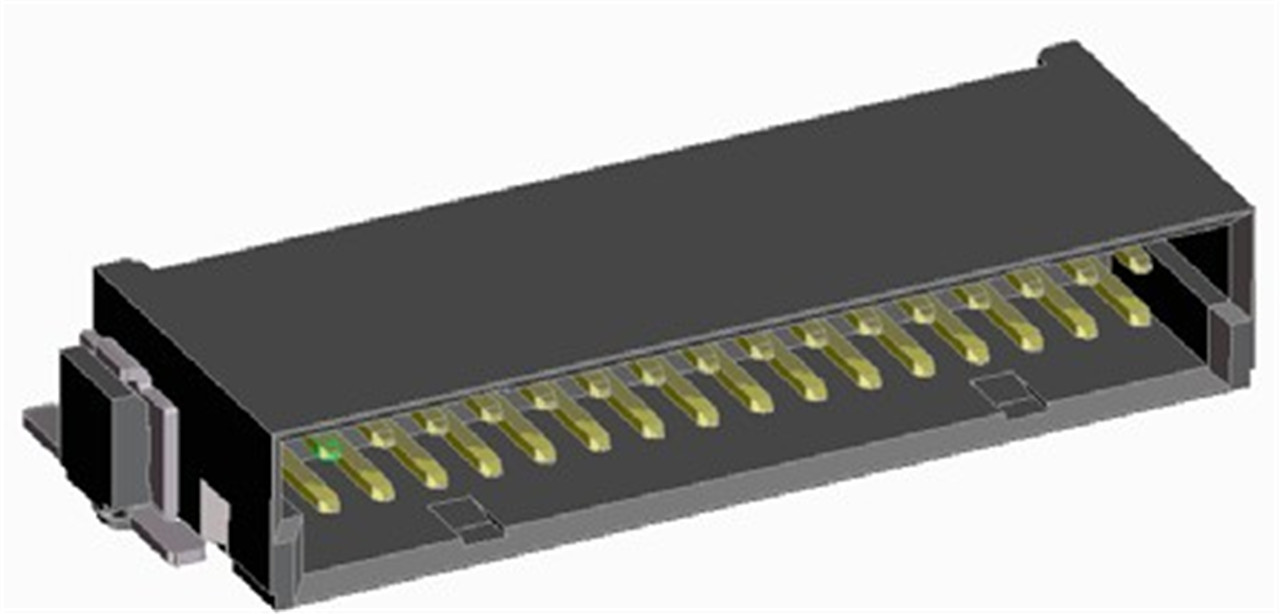

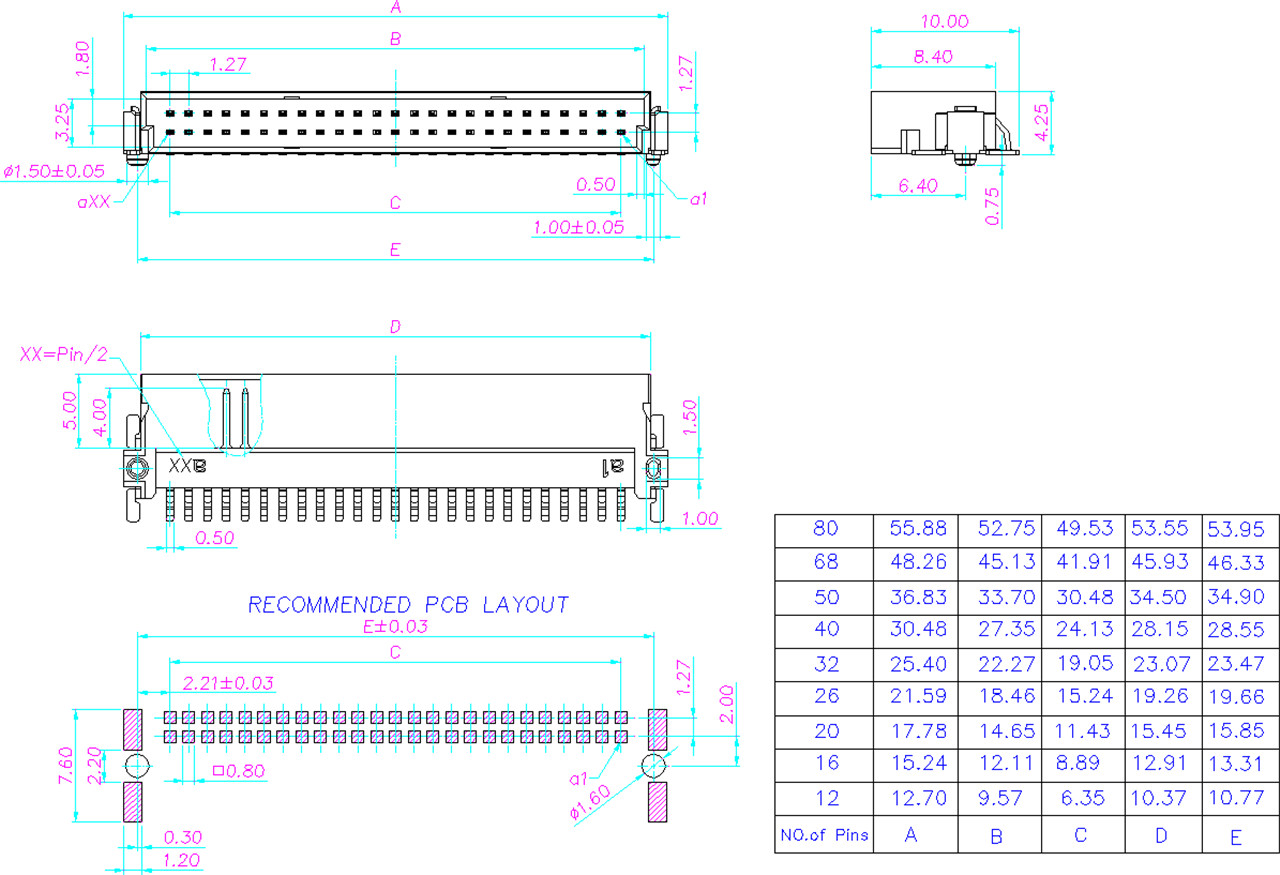

● Sawirrada cabbirka

Fikradda

● Astaamaha

| Garoon | 1.27mm |

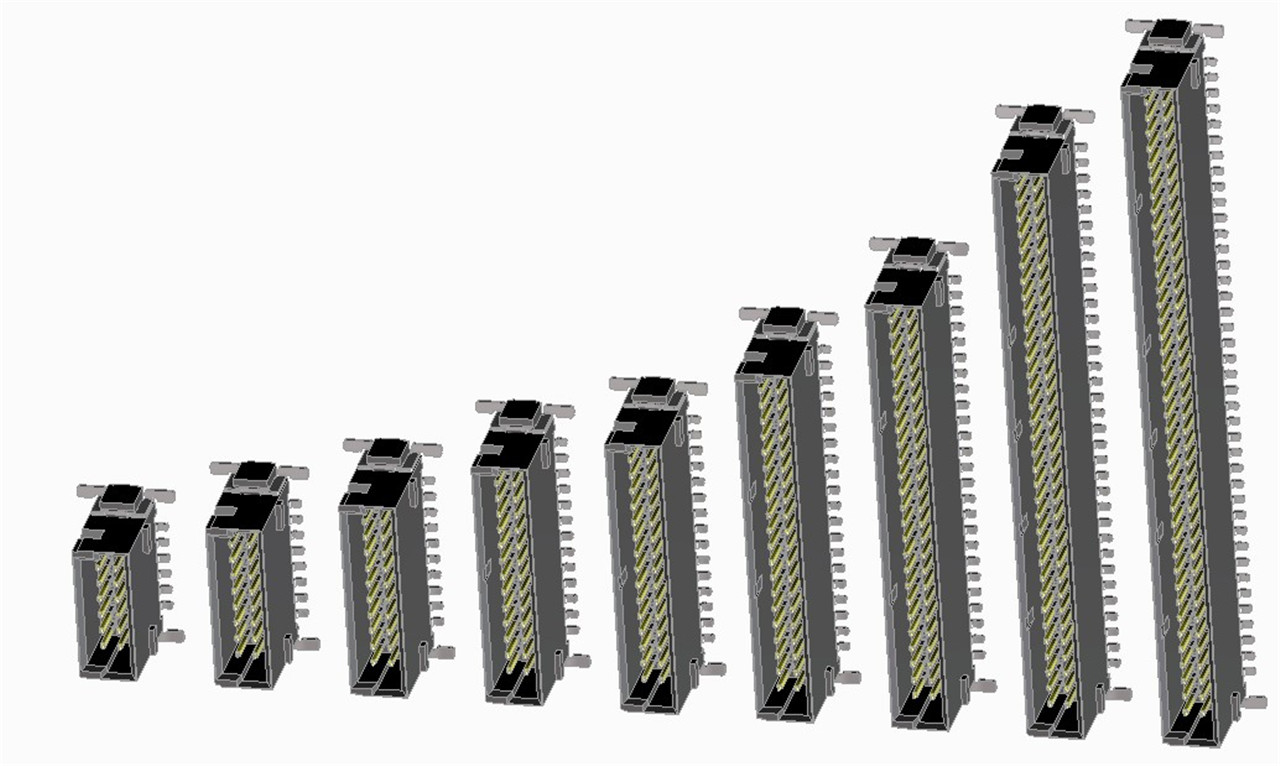

| Tirada biinanka | 12, 16, 20, 26, 32, 40, 50, 68, 80 |

| Tignoolajiyada joojinta | SMT |

| Codsiyada | Heerka xogta ilaa 3 Gbit/s Qiimaynta hadda jirta ilaa 1.7 A xidhiidhkiiba xidhiidhyada Board-to-board: - isku dhejisan (Mezzanine) - orthogonal |

| Xidhiidhiyayaasha | Xidhiidhiyayaasha lab: xagal toosan iyo midig Xidhiidhiyayaasha dheddigga: xagal toosan iyo midig |

| Noocyo gaar ah | Xiritaanka tooska ah wuxuu gaari karaa dhererka 20 ~ 38mm, waxaana la dooran karaa noocyo kala duwan oo dherer ah oo dhejis ah. |

Faa'iido

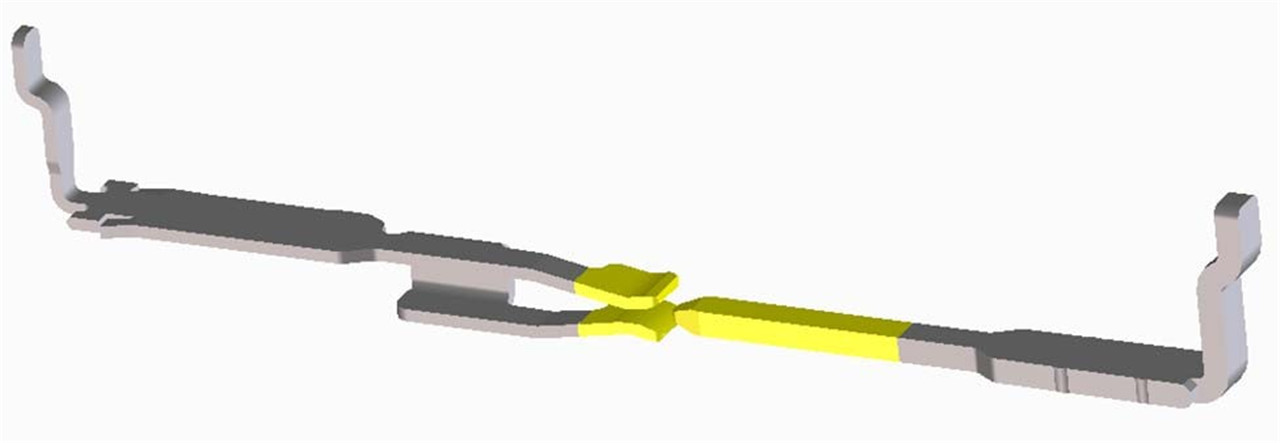

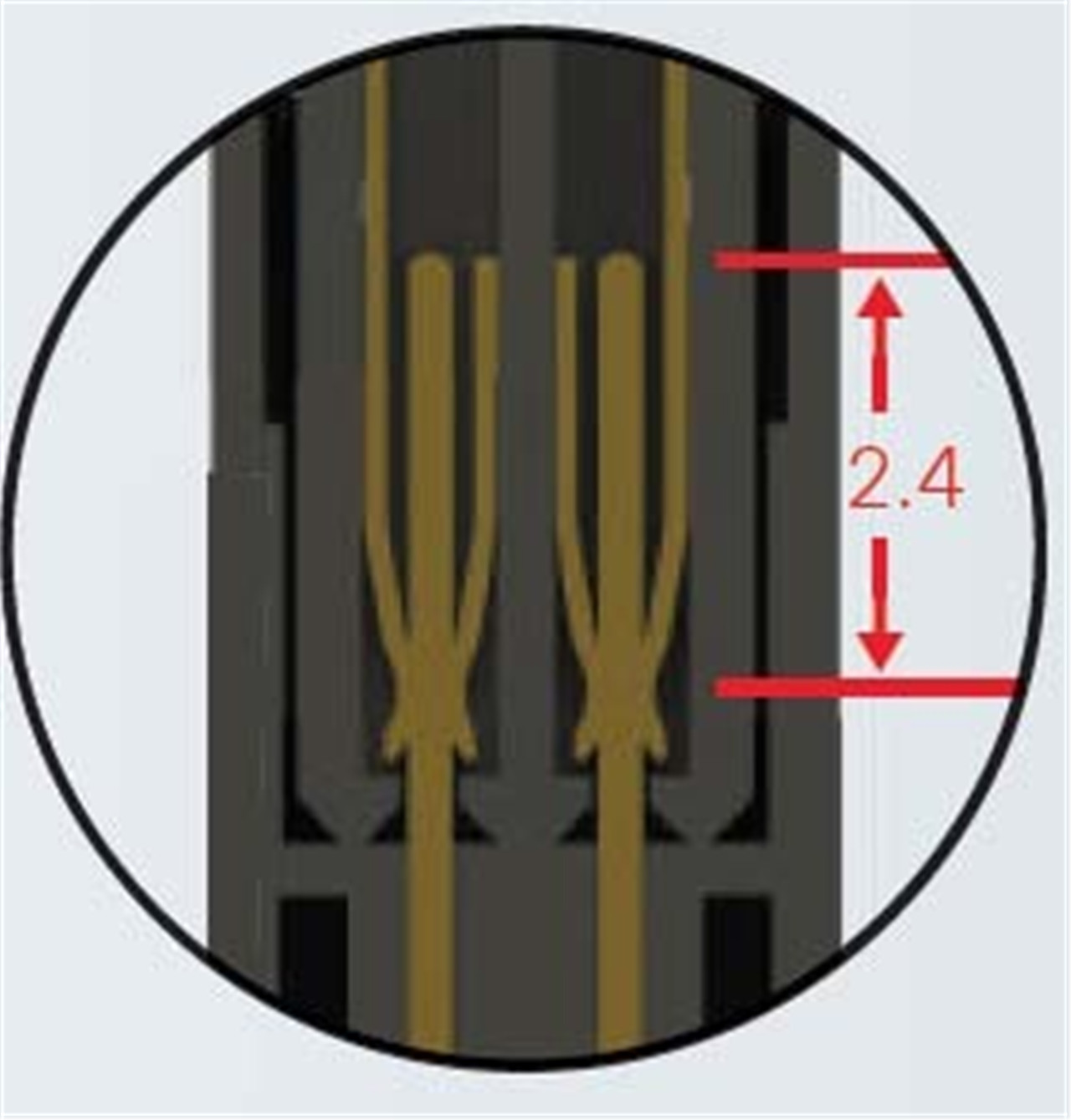

● Naqshadaynta Xiriirka Sare ee La isku halleyn karo

1. Terminal dheddig oo xiriir la leh oo aad loogu kalsoon yahay

2. 90° torsion spring terminal

3. Dusha duuban waxay leedahay qaab isku mid ah si loo hubiyo in marinnada si adag loo geliyo

4. Meel weyn oo xiriir ah oo ka dhexeeya terminalka lab iyo dhedig

5. Qallooc aad u hooseeya oo dusha sare ah, yaraynta xidhashada dusha sare

6. Iska caabbinta xiriirka hoose

● Wajiga kala-baxa/is-daawashada

1. Naqshadaynta nacasnimada ee dusha sare ee lammaanaha si looga hortago gelinta khaldan iyo khaladaadka isku xirka

2. Gawaarida ku wareegsan caagga waxay hubisaa dulqaad weyn oo hagaha

3. Naqshad hal dalool oo gaar ah ayaa sahlaysa gelinta saxda ah

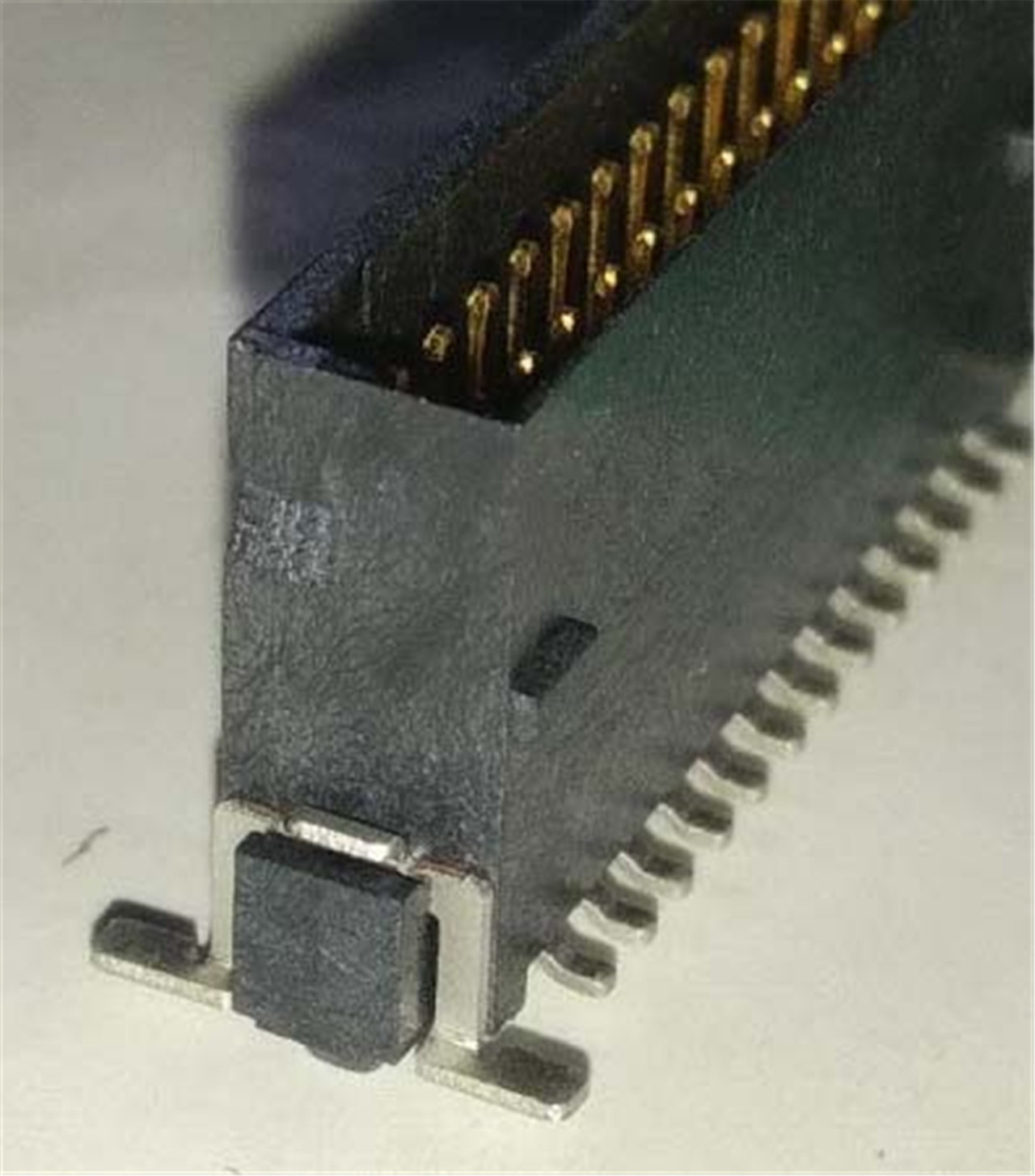

● Xargaha Iibka Adag

1. Awood haynta heer sare ah ee looxa wareegga

2. Qaybta go'an waxay nuugi kartaa diiqada farsamada waxayna u adkeysan kartaa saameynta sare iyo culeyska gariirka

3. Xidhiidhiyayaasha SMT waa kuwo adag oo la isku halayn karo, iyaga oo hubinaya iska caabbinta jeexjeexa iyo jeexjeexa ku filan (tusaale: xoogga dhogorta: ugu yaraan 1000 N; caabbinta ilmada: ugu yaraan 100 N)

● Fogaanta is jiid jiid

1. Fogaanta is jiid jiidka weyn waxay bixisaa isku halaynta xiriirka waxayna magdhoweysaa dulqaadka u dhexeeya dhererka kala duwan

● Meelaynta Tiirka

1. Geometries kala duwan ee boosaska meelaynta waxay xaqiijinayaan meelaynta saxda ah ee looxa wareegga

2. Si loo gaaro magdhowga ugu fiican ee godadka PCB ee dulqaadka togan iyo kuwa taban

Habaynta

● Cajalad iyo Gariir

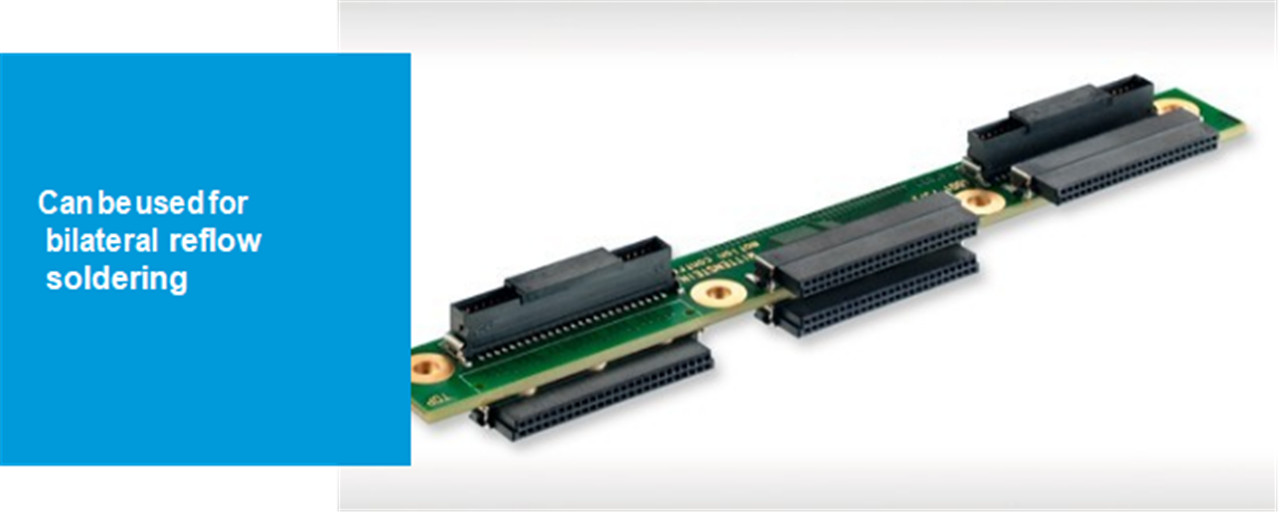

● Isku-uruurin Toos ah oo Dhamaystiran iyo Alxanka Dib-u-qulqulaya

Dib-u-socodka Dib-u-socodka

Dalbashada Macluumaadka

| Tirada biinanka | Baakadaha | Lambarka Qaybta |

| 12 | Cajalad iyo gariir | 127H02-12-X-R0 |

| 16 | Cajalad iyo gariir | 127H02-16-X-R0 |

| 20 | Cajalad iyo gariir | 127H02-20-X-R0 |

| 26 | Cajalad iyo gariir | 127H02-26-X-R0 |

| 32 | Cajalad iyo gariir | 127H02-32-X-R0 |

| 40 | Cajalad iyo gariir | 127H02-40-X-R0 |

| 50 | Cajalad iyo gariir | 127H02-50-X-R0 |

| 68 | Cajalad iyo gariir | 127H02-68-X-R0 |

| 80 | Cajalad iyo gariir | 127H02-80-X-R0 |